With the rapid development of the global new energy industries,DC-DC converters are widely used in charging, wind power, hydrogen production, and the other key applications.Bothmanufacturersandenduserslookintominiaturizationof the systems, yet with same or higher power density and efficiency.

The size and cost of the DC-DC converter are directly related to the built-in inductive components. Legacy IGBT-based DC-DC converters for high-power applications usually work at frequency range of 10-20kHz. With the increase of frequency, the system loss and heat generation will grow significantly. As a solution to operate at higher frequency, a multi-level design can be used, but this will bring along more complex design, significantly increased number of additional components, more complex control, and less reliable overall system. The problem can be solved by using silicon carbide semiconductors.

SiC devices provide excellent high-frequency performance (high switching frequency and very low switching losses) and low on-resistance characteristics. Using SiC you can can achieve higher efficiency, higher power density, and higher reliability. Today siliconcarbide has become a perfect device solution for high-power DC-DC converter applications.

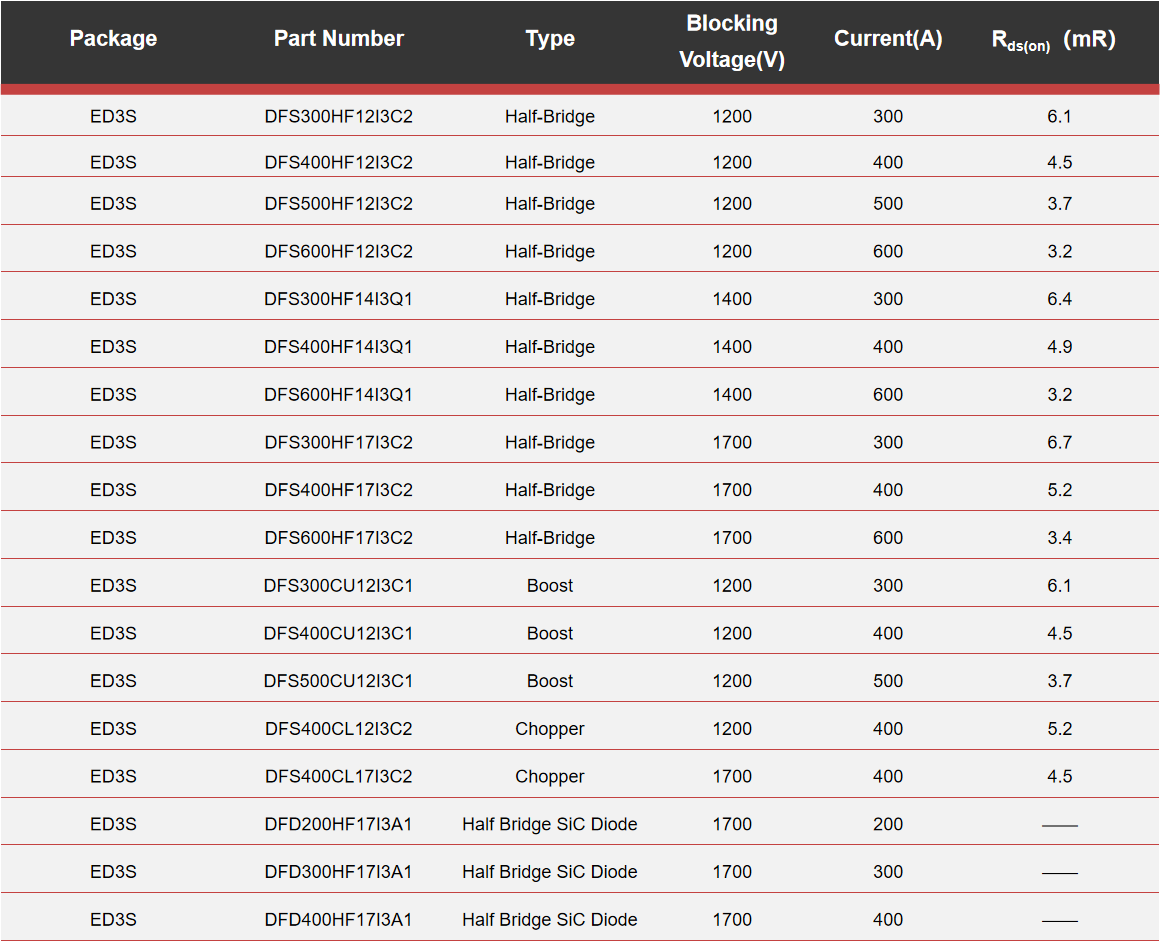

To support manufacturers with reliable SiC power devices,Leapers Semiconductor offers a family of ED3S SiC power modules in a range of 200-600A, 1200V/1400V/1700V. To meet the requirements of the end users, today Leapers Semiconductor offers this product family in Half-Bridge, Boost, and Chopper topologies:

· Half-Bridge ED3S SiC modules are widely used in isolated DC-DC and Buck-Boost converters typical for battery testing equipment, energy storage systems, etc.

· Boost modules are used in fuel cells, DC microgrids

· Choppers are used in hydrogen production power supplies, heavy duty trucks’ charging

Using ED3S series SiC power modules, the frequency was increased from the average 10-20kHz to 80kHz. Besides, the conversion efficiency reached >99% with power density per unit volume of the DC-DC converter has been increased exponentially.

ED3S SiC Power Modules feature:

· Compact design which is only 2/3 of the industry standard EconoDUAL™3

· Power terminals that are stacked to reduce parasitic inductance and switching noise

· High-performance epoxy resin potting which contributes to high reliability and moisture resistance

· Thermal resistance that is as low as 0.040k/W (for 1.7kV/600A model -DFS600HF17I3C2) - industry-leading level

All ED3S SiC power modules have passed customers’ qualifications and are being mass produced. Get in touch withLeapers Semiconductor team to learn more!